Resources

Existing at the technical intersection of Ophthalmology, Engineering, and Design, ORBIT Lab has access to a multitude of resources, including: the Ophthalmology NIH-funded imaging, animal, and machining core services, rapid prototyping via 3D printers, CAD design software, customizable software and circuitry development.

3D Modeling Heading link

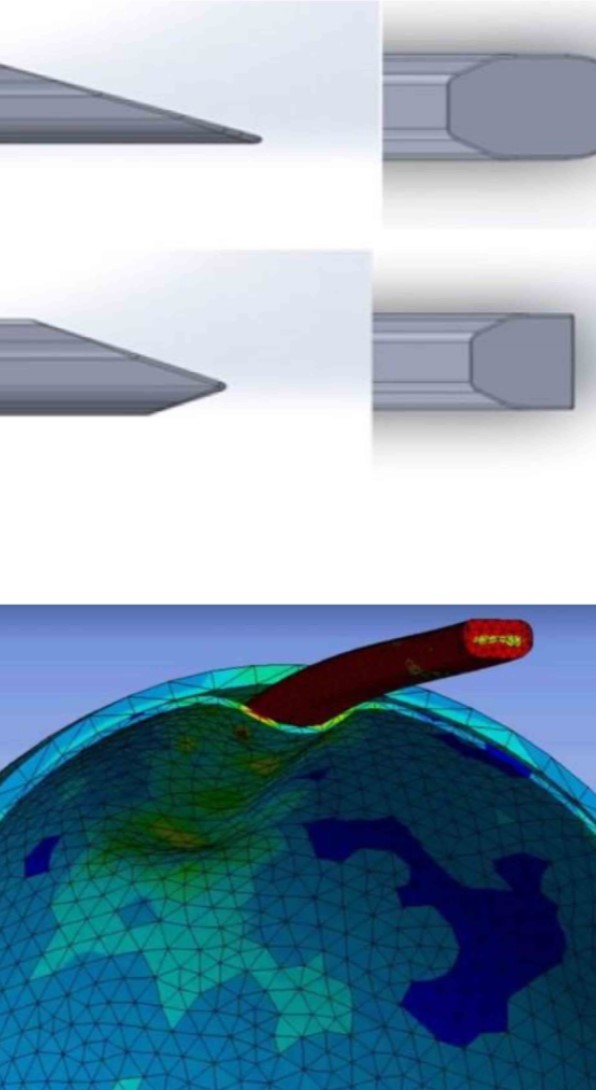

The ORBIT Lab team can create 3D models of potential solutions for visualization, Finite Element Analysis, or printing.

Rapid Prototyping Heading link

Prototypes are used throughout research and development, with a focus on fast production to aid in the iterative testing and validation process. Methods include 3D printing, CNC milling, laser cutting, and Arduino programming.

Benchtop & Ex Vivo Testing Heading link

As part of our process, ORBIT Lab focuses on determining prototype efficacy via benchtop rig or ex vivo eye studies before returning the prototype to the project sponsor for more in-depth research.